ELECTRONICS MANUFACTURING - APEX 2024 - FACTORY INSIGHTS & CO-NECT

Key Takeaways from the IPC APEX Expo 2024:

A Showcase of Innovation and Partnership

April 25th, 2024

By Davina McDonnell, Manager – Marketing & Product Management

By Davina McDonnell, Manager – Marketing & Product Management

Introduction

The IPC APEX Expo 2024, held in Anaheim from April 9th to 11th, is one of our favorite shows – the perfect place for those of us in electronics manufacturing to present our latest technologies and nurture pivotal partnerships. Here, we’ll recap the highlights and key takeaways from Cogiscan’s perspective, specifically highlighting our commitment to innovation and collaboration in this industry.

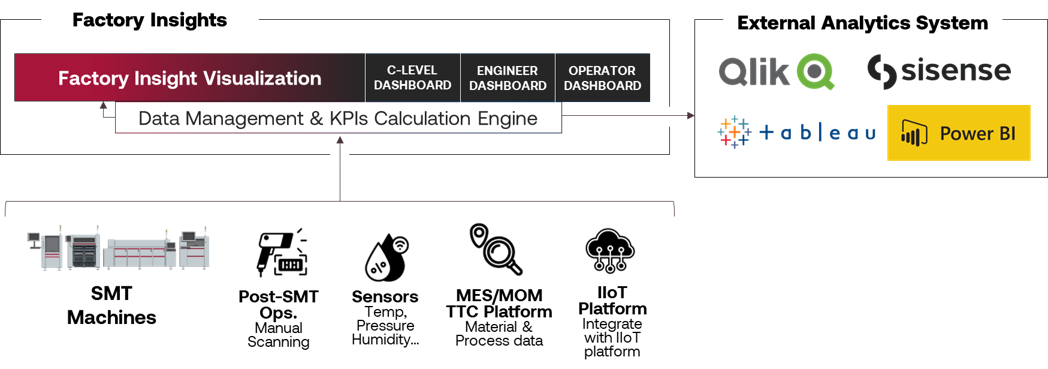

Factory Insights: A Launch Like No Other

We launched our newest product, Factory Insights, a fully customizable analytics platform built specifically for the nuances of electronics manufacturing. The market response was overwhelmingly positive, and we enjoyed showcasing the platform’s capabilities to a wide audience, including current and potential customers. For our sales team, it was energizing to demonstrate the versatility of this analytics platform with a resounding “Yes, we can do that” to nearly all customization inquiries. The customizability of Factory Insights was a consistent highlight, capturing the attention of key industry players and setting a new standard for analytics solutions.

A New & Exciting Partnership

Our team had the pleasure of working with Koh Young's experts to implement Factory Insights as a complementary solution to K-Smart within a mixed-vendor ecosystem at the Koh Young booth. This collaboration proved to be a testament to what can be achieved when trust and credibility come together seamlessly. Integrating to Koh Young’s machines was accomplished in a matter of minutes, exemplifying the ease of accessing and visualizing meaningful KPI data in the new Factory Insights platform. If you haven’t watched it yet, here’s an interview from APEX our Product Manager Julie Cliche-Dubois did in collaboration with Ivan Aduna, Global Smart Factory Manager from Koh Young Americas.

Celebrating Established Relationships

In addition to forging new partnerships, we relish the time we get to connect with long-standing collaborators like Juki and Essegi. The continuous proactive support from our partners is invaluable to us, and it’s truly delightful to come together in-person to not only plan about future strategic endeavours but to also reminisce about past deals and projects.

Our channel partners, including the diligent team from Horizon Sales, also played a crucial role in the success of APEX. Their strategic planning and impeccable organization are so helpful in ensuring our sales and technical teams are available for customer meetings. Their efforts did not go unnoticed, and they were instrumental in enhancing our overall experience of the show.

Our channel partners, including the diligent team from Horizon Sales, also played a crucial role in the success of APEX. Their strategic planning and impeccable organization are so helpful in ensuring our sales and technical teams are available for customer meetings. Their efforts did not go unnoticed, and they were instrumental in enhancing our overall experience of the show.

Connectivity: Still the Heart of the Industry

While talking with prospects, customers, and partners, it’s clear that connectivity remains a critical issue for so many, from contract manufacturers to equipment vendors. The challenge of creating seamless connectivity and data exchange within mixed-vendor ecosystems persists, and it's clear that the quest for improved factory connectivity is ongoing. Co-NECT’s architecture, built on a foundation of adaptability, promises to deliver robust connectivity solutions that are customizable to the unique requirements of each manufacturing floor. We’ve illustrated how Co-NECT integrates disparate systems, provides a unified and coherent data exchange framework that enhances productivity and minimizes downtime. The interest for Co-NECT at APEX re-emphasises the industry's acute need foundational data exchange and reinforces our role as a key player in developing solutions that navigate and unify the complexities of modern manufacturing ecosystems.

Our COO, Audry Larocque, entered our industry with a bang – joining several technical discussions with different IPC Committees. Our increased involvement is a sign of our commitment to shaping the future of connectivity, AI, and data management in electronics manufacturing. These discussions are just the beginning, and we look forward to participating in helping to shape the future on these critical subjects.

Our COO, Audry Larocque, entered our industry with a bang – joining several technical discussions with different IPC Committees. Our increased involvement is a sign of our commitment to shaping the future of connectivity, AI, and data management in electronics manufacturing. These discussions are just the beginning, and we look forward to participating in helping to shape the future on these critical subjects.

Looking Ahead with Anticipation

We’re already looking forward to returning next year for another exciting show, where we will continue to meaningfully contribute to the evolution of the electronics manufacturing industry.

In conclusion, our experience at the IPC APEX Expo 2024 was marked by a successful product launch, strengthened partnerships, and future-oriented strategic discussions. Enormous thanks to all of you who took the time to connect with our team at the show.

In conclusion, our experience at the IPC APEX Expo 2024 was marked by a successful product launch, strengthened partnerships, and future-oriented strategic discussions. Enormous thanks to all of you who took the time to connect with our team at the show.

Designed for the unique needs of circuit board

assembly & complex manufacturing ecosystems

assembly & complex manufacturing ecosystems

You might also like